The perspectives of development of the construction branch in the years to come are promising. The greatest revival can be expected by 2020. It is related to the execution of due investments and the need to complete the EU projects. Therefore it is worth paying a close look to the aggregate market, which is inseparably bound to the most traditional segment of business activity of PROJPRZEM MAKRUM S.A. – the segment of crushing and grinding machines.

We have tried to observe its development for a very long time. An important event was the conference “the Development of Aggregate and Crushing Machines Market in Poland” organized two years ago at the University of Technology and Life Sciences in Bydgoszcz, during which we reflected on the most important problems and challenges for this branch as a group of practitioners and scientists. Today it is worth returning to the issue specified in the title of the seminar. Let’s start from the very aggregates, which are the basic raw material used primarily in construction industry. However, it must be remembered that they are also used in other branches, e.g. the cosmetic one.

The aggregate is the material of mineral or organic origin. The first type is commonly used in construction, however the potential of the second type is mentioned with increased frequency. Organic aggregates can be valuable for the construction industry mainly after their combination with non-organic materials. Attention is paid primarily to the ecological aspect of such solution. He ISOBIO project, supported by the European Union under “Horizon 2020” is aimed at the popularization of organic aggregate use.

However, today it is the mineral aggregate type that is mainly used as raw material in construction. Teresa Rucińska, Ph.D., Eng. defines them as grainy construction material that is actively used in the process of preparation of mortar, concrete, mineral and asphalt mixes, bearing layers of road surfaces or frost-resistant or filtration layers, etc. The division of aggregate is made also on the basis of a range of different features, including the manner of acquisition and the raw material type from which they originate, their grain size or density.

The intended use of aggregates depends mainly on their properties. Even those ones with relatively low resistance can be used e.g. as decorative elements. Plaster can serve as an example, which is used not only as wall protection, but also as a decorative solution. Japanese plaster, which effectively matches modern interiors, can be mentioned here. An interesting fact is that it contains cotton and silk (among others). On the other hand, the aggregates with high durability are mainly used in road construction industry.

According to the report “Aggregates in the construction industry”: 91% of the aggregates come from natural deposits, 5% come from recycling, 2% come from maritime areas, and the remaining 2% are artificial aggregates. The value of these goods is confirmed by the current sand prices. It is exported even to the places where it is seemingly abundant. However, the sand present in the Arab countries is not fit for industrial use. Such high demand for sand is definitely related to the expansion of construction in nearly every nook and corner of the world. The mention of Singapore became quite popular in this context:

Singapore had no sand resources of its own, which were necessary for the creation of artificial land, so it had to import the sand. In 1997 the authorities of this country prohibited further export. So Singapore companies started to exploit Indonesia- and they destroyed 24 small islands. Today they are not present on the maps. In 2007 the government of Indonesia also introduced the sand embargo. The price of the ton of sand in Singapore went up from 3 to 190 dollars!

In Poland mainly gravel and sand aggregates are produced, which are mainly used for the production of concrete and concrete goods, used both in housing construction and road industry. Their deposits are present on the territory of nearly the whole country. Another situation takes place in the case of crushed aggregates (obtained mechanically), which are mainly mined in the southern regions of Poland. Crushed aggregates are the basic material used on road and railway construction.

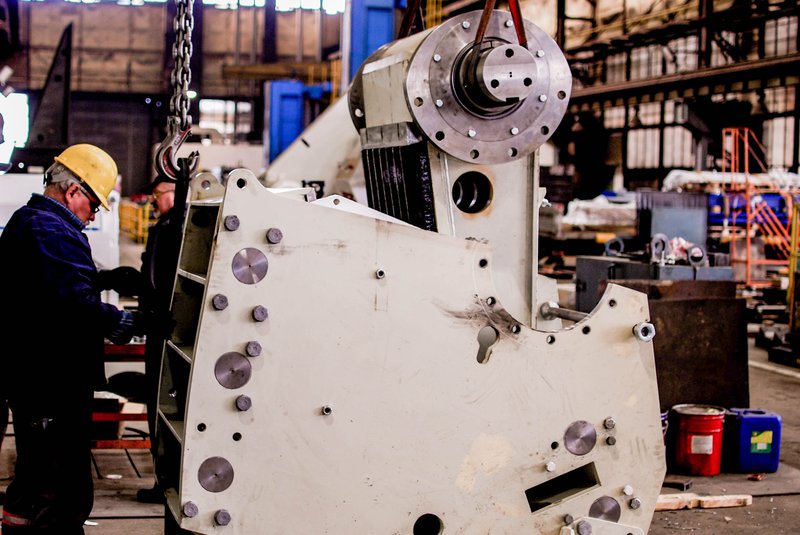

Does an optimistic forecast for the construction branch also mean good news for the aggregate market? It definitely does. The increase of aggregate mining could be clearly observed for example in the years preceding the organization of EURO 2012 in Poland, which was related to the need to prepare an adequate infrastructure. However, it should be remembered that this relation is not a direct one. The development of the market also depends on many other factors, including the quality of raw materials, the costs of transport or aggregate availability. An appropriate technology is also extremely important. Since we know that the provision of modern solutions for the production of aggregates is of the highest importance, we recently introduced an innovative HJ crusher into our portfolio.

The crusher offers the possibility of crushing hard and medium-hard materials, such as diabase, granite, basalt or clinker. It ensures the easy regulation of the gap in the full scope, the possibility of selection of an appropriate jaw and the maximum capacity in its class. It also has an ergonomic and compact body. The machine is also equipped with a wide range of jaw types, the use of which depends on the material to be processed.

- A standard one of universal use for non-abrasive rocks.

- Wide teeth for very hard and abrasive materials or dynamic control of set points in the hydraulic system.

- Round teeth for gravel and rocks with increased manganese content.

- Special teeth for blocks decrease the risk of non-crushing of flat raw materials.

- Wide waves for asphalt recycling, minimizing jaw jamming.

- Waves for the recycling of concrete, bricks and demolition waste.

It should be remembered that it is necessary to pay attention to the following items with the view to obtaining optimum operating parameters: the appropriate selection of the jaws, correct raw material grain size, appropriate raw material feeding speed, adequate capacity and width of the feeder and the reduction of clay and loam contaminations.

[1] http://www.focus.pl/artykul/czy-czeka-nas-globalna-wojna-o-piasek

[2] http://docplayer.pl/15260372-Kruszywa-w-budownictwie-cz-2-kruszywa-alternatywne.html

[3] http://trucinska.zut.edu.pl/fileadmin/Kruszywa_budowlane.pdf

Opracowanie: Agnieszka Kuca, źródło: MAKRUM.