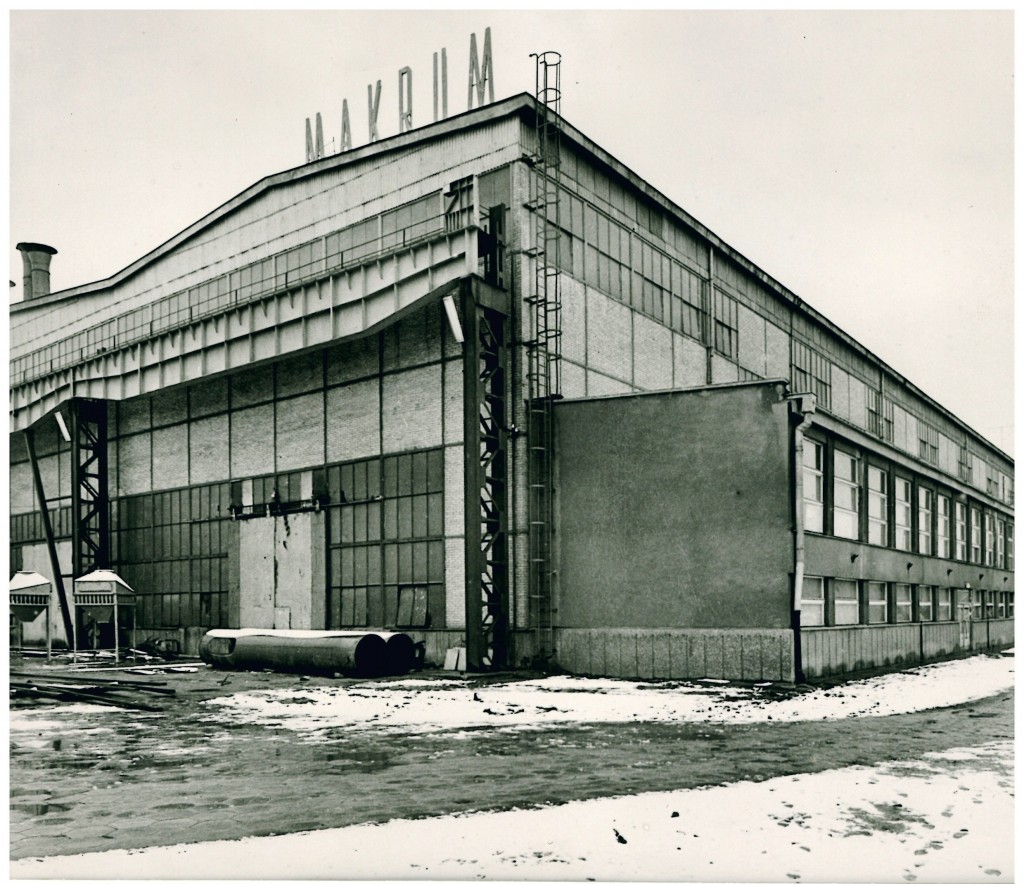

The year 2018 will mark an exceptional time for PROJPRZEM MAKRUM S.A. The Group’s largest brand – MAKRUM – is celebrating its anniversary. It can boast a history of activity of nearly 150 years. On an occasion of such an impressive jubilee we would like to present a series of documents devoted to MAKRUM activity over years, accompanied by a rich photographic record of that time.

Read more about MAKRUM’s history:

– part 1: Hermana Löhnert’s legacy

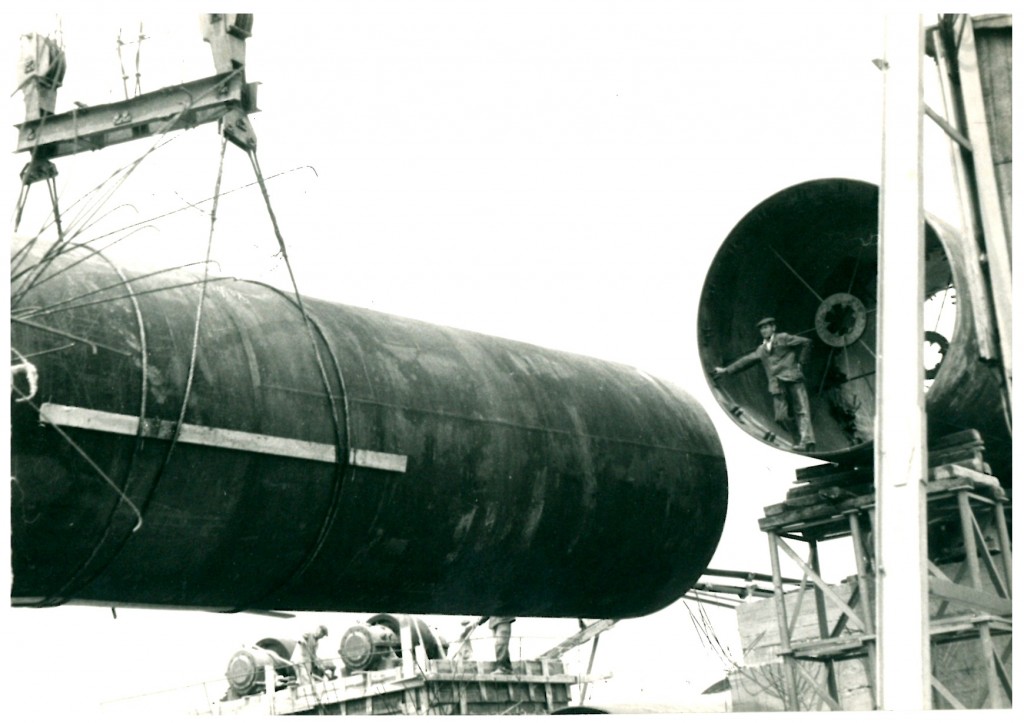

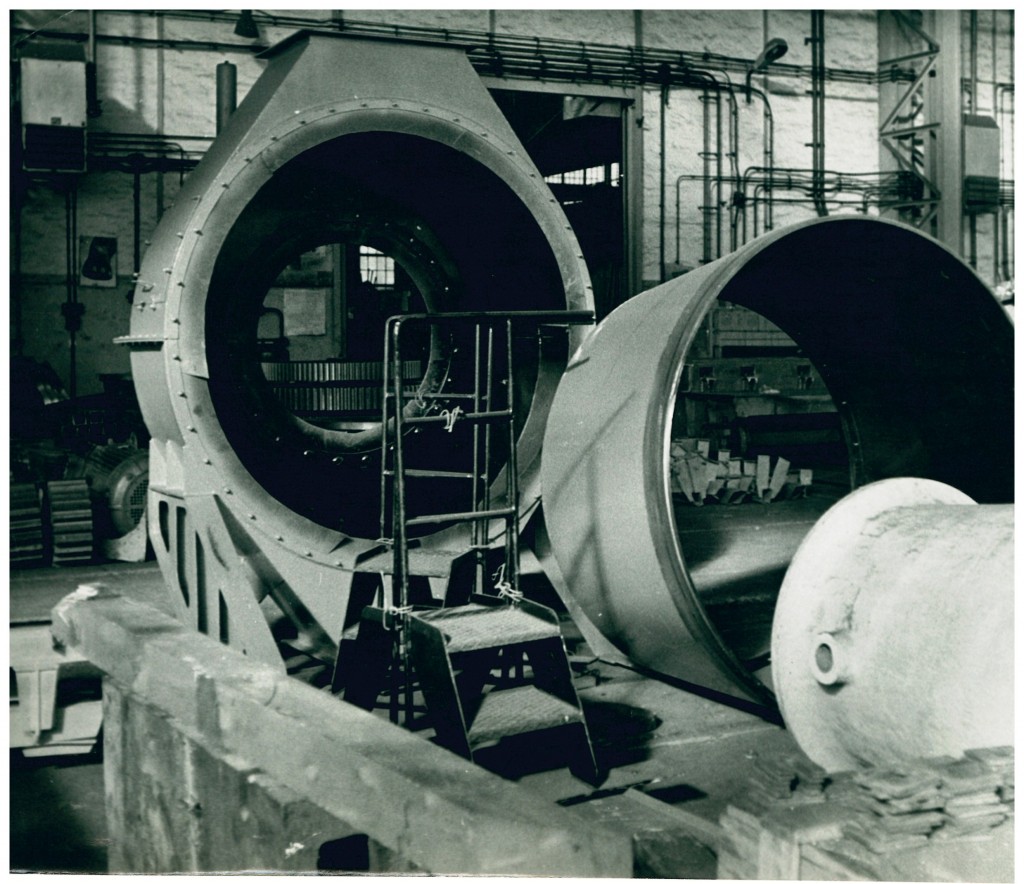

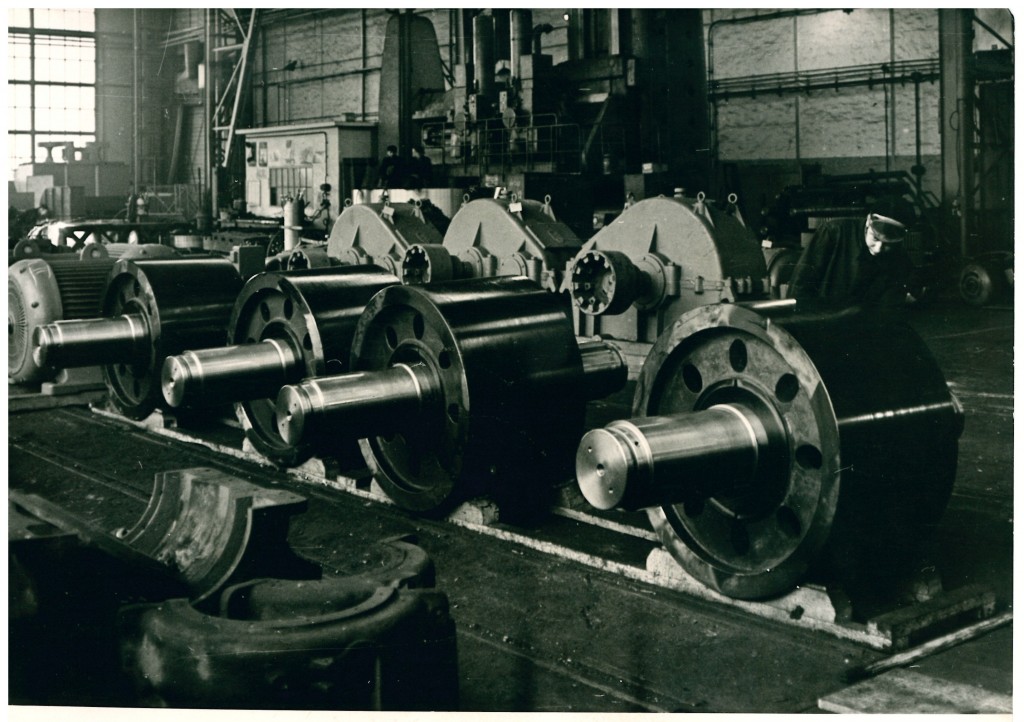

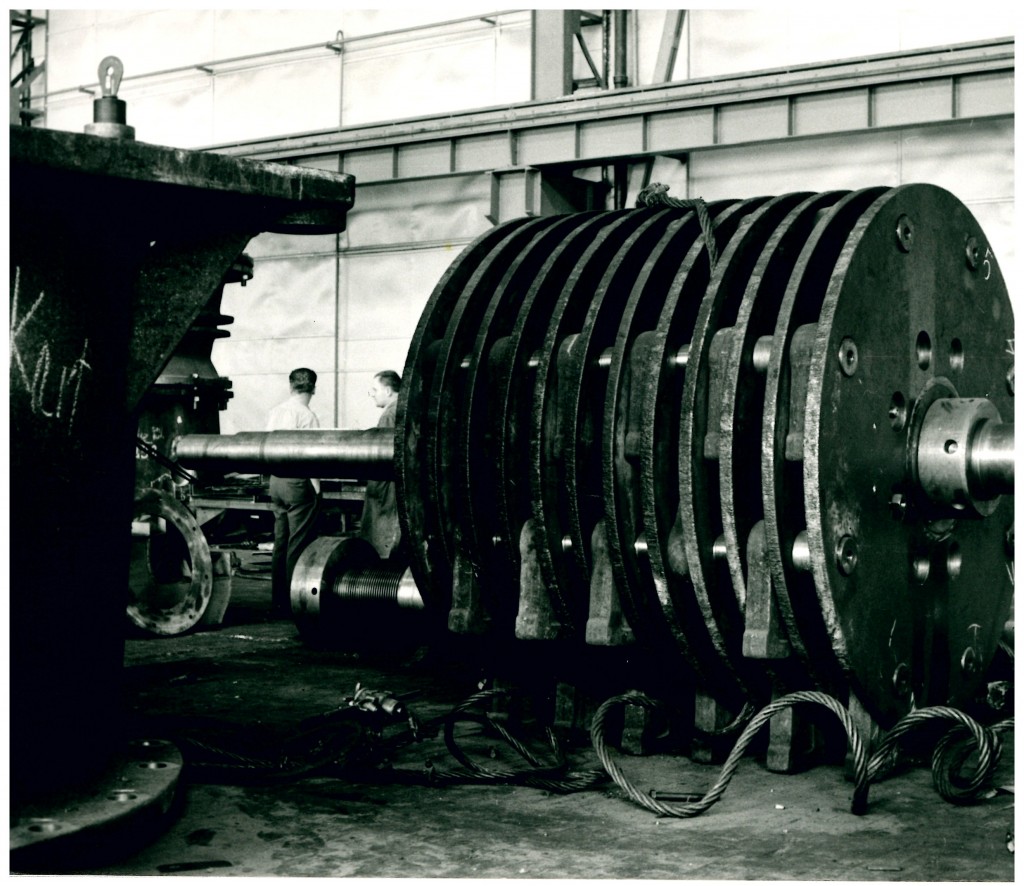

After declaring insolvency of the pre-war MAKRUM, in 1938 a Lessors’ Company named Pomorska Fabryka Maszyn Spółka z o.o. was brought to life in Bydgoszcz. Owing to this the company could return to its extensive activity – the production of crushing machines, narrow gauge railway rolling stock as well as machines and equipment for cement factories, sugar refineries and brickyards as well as various types of boilers and containers. During World War II the production profile was altered to meet military requirements (among others, sections of submarines, lifts, anchors and iron castings were produced). In 1946 the factory was nationalized. At the same time, a higher level of employment was restored – in early 1948 the factory employed 815 persons, while in 1954 – 1200 persons.

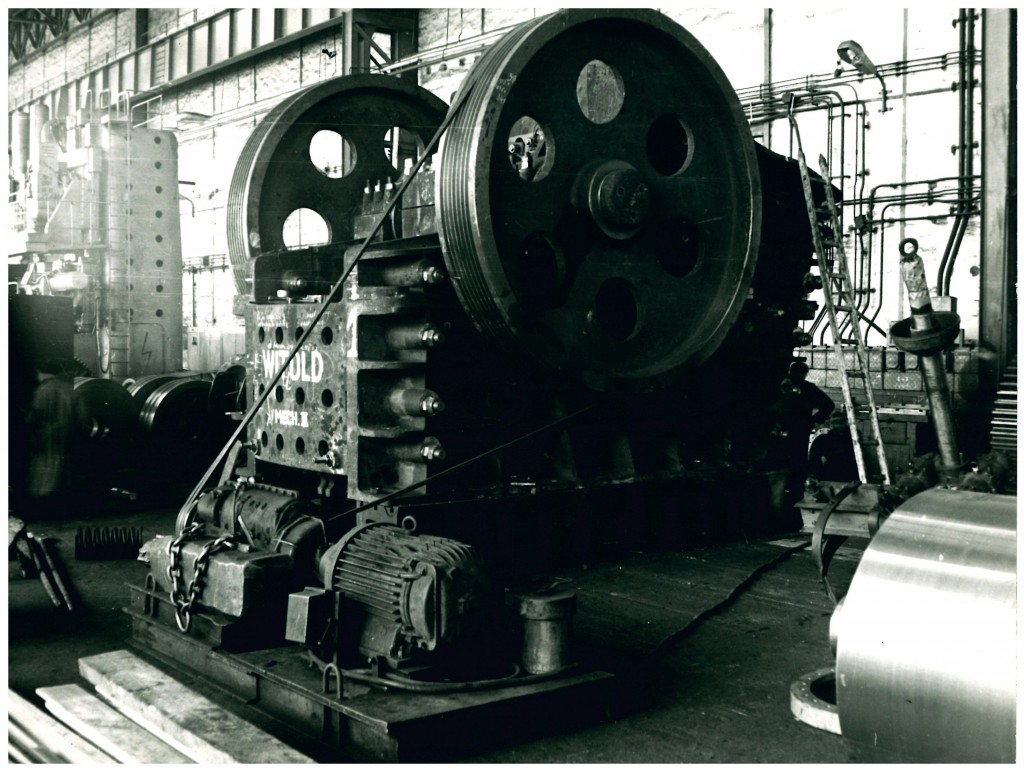

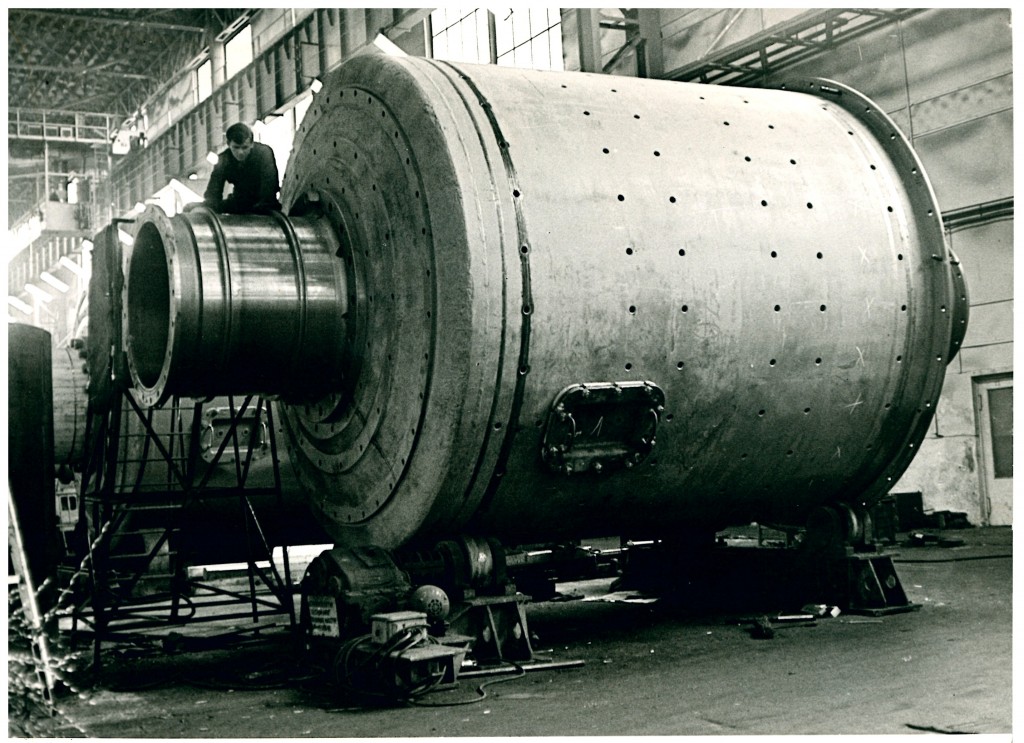

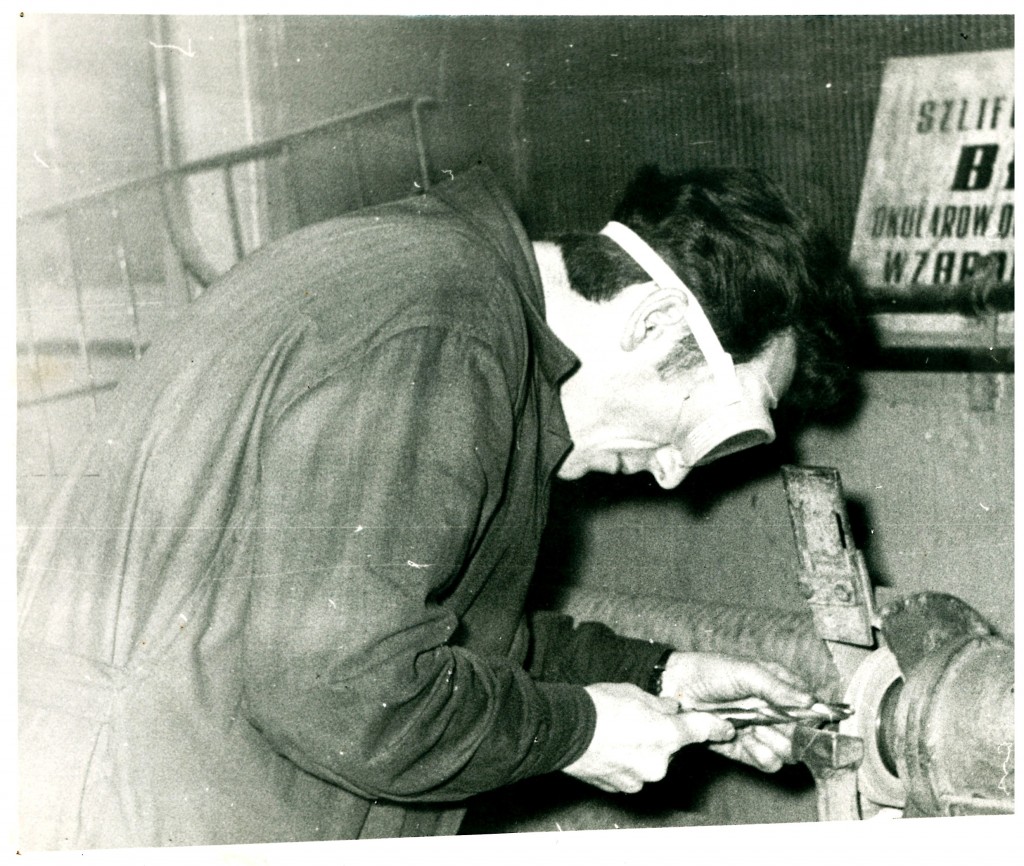

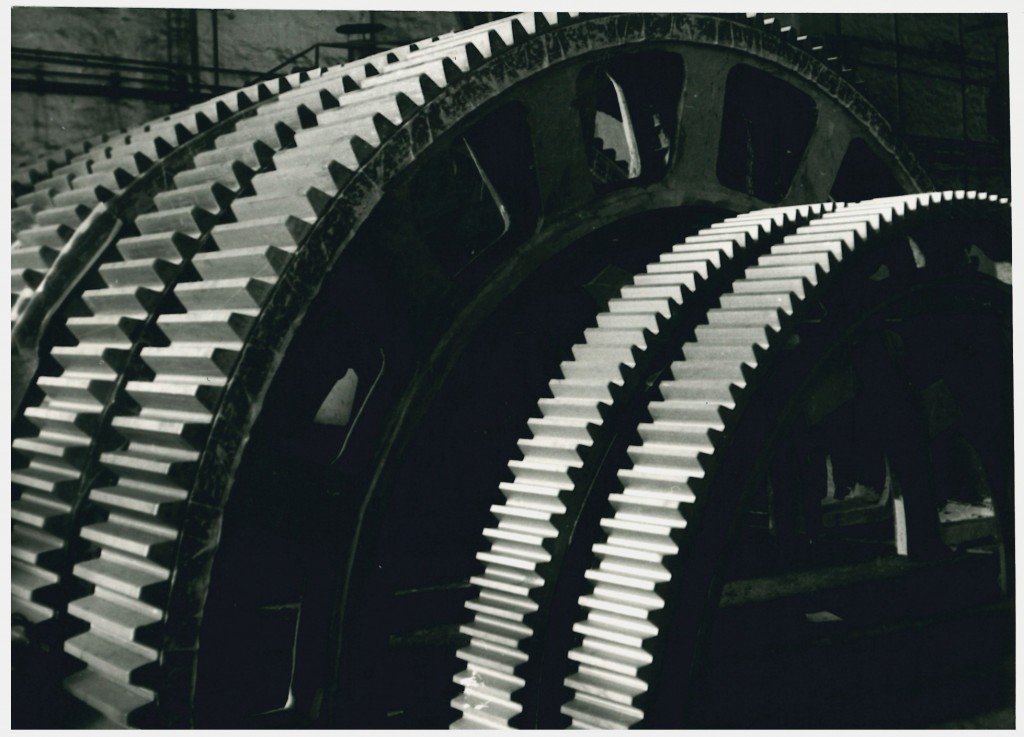

In the 1950s and 1960s the factory underwent excessive expansion by erecting a machining hall, an assembly hall and an iron casting plant with a compound of auxiliary facilities. In 1957 it was merged with the former Hans Eberhardt Bydgoska Fabryka Maszyn i Kotłów Parowych [Machine and Steam Boiler Factory of Bydgoszcz] and smaller plants. In this form, the company adopted the name of Pomorskie Zakłady Maszyn “Makrum”. The MAKRUM name is an acronym that represents flagship products of the plant: crushing and milling machines. Another stage of the plant development took place in the years 1962-1967. It aimed at a further reconstruction of manufacturing halls and equipping them with large appliance machining devices. The 1970s saw the automatization of production.

In the 1960s and 1970s the company maintained a large-scale production, thus becoming a recognized manufacturer of machines and industrial equipment. 60% of the production comprised serial machines and equipment, while 40% represented custom-made single products. Since 1975 the plant has had its own construction office that prepared the entire technical documentation of machineries and cement factories.

Sporadically, the company executed orders for clients from Western countries, while concentrating its exports on the East. The orders were placed mainly by the COMECON and Arab countries, the majority of which came from Libya, Pakistan, Kuwait, North Korea, Vietnam as well as the USSR, GDR, Bulgaria, Mongolia and China.

The export helped build, among others, a cement factory in Fallujah, Iraq, a lime plant in Karbala, a cement milling plant in Kuwait and in Beremend, Hungary; other facilities were erected in Bulgaria, Czechoslovakia and the USSR. The most experienced employees of the company have preserved living memories related to working in such distant and exotic countries.

Part of Polska Kronika Filmowa from 1960 about export of crushing and grinding machines from Bydgoszcz’ factory: http://www.kronikarp.pl/szukaj,12792,tag-689415,strona-6